Bedrock Excavation with Adjacent Sensitive Structures

Excavation of bedrock adjacent to aging or historic historic structures on problematic foundations is not a task for the faint of heart. Blasting is definitely a no-go and large impact hammers can cause seismic waves that propagate and cause micro or macro fractures well away from the work zone, potentially weakening the existing foundation leading to cracking or in the worst case, collapse. Moreover, hydraulic hammers are not suited for such “dental work” where precision rock removal is required. Unintended overbreak is also a significant risk.

This is a case where RockWheels are often the tool of choice.

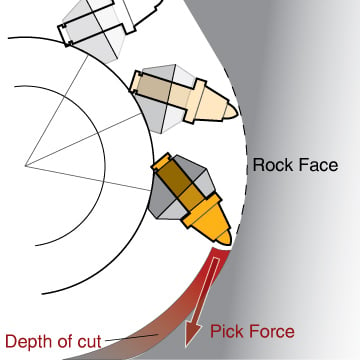

Through a high-torque (up to 41,400 ft lb), low-speed (60-120 rpm) cutting action rock grinders attack the shear strength of the rock by “raking” at a 45°-50° angle with conical carbide tipped teeth (picks). Cutting drums typically have 50-80 picks depending on width. Picks are arranged in a spiral fashion with successive picks offset laterally. As the rotating drum cuts, picks overlap the fracture zone created by the ones ahead.

The result is an excavation mechanism vastly different from hammers (cutting vs. breaking) and much lower vibrations compared hammers. Smooth, continuous cutting keeps disturbance to surrounding rock and structures to a minimum. Rock can be removed rapidly and with a precision simply not possible with hammers. Tight corners can be milled and walls and bottoms can be made smooth. Another benefit is the usability of the cuttings. Instead of hauling off large rocks and crushing and disposal, the milled rock (typically 1”-3”) can be reused on site as bedding or back fill eliminating costs associated with transport.

Recently an Rockwheel D30 (150hp) was successfully on a Komatsu PC390 in Bellefonte, Pennsylvania just across the street from the historic courthouse built in 1805. Limestone bedrock with a strength of 15,000-20,000 psi was successfully cut without disturbance to adjacent historic brick buildings or the underlying rock.