Low Noise/Low Vibration

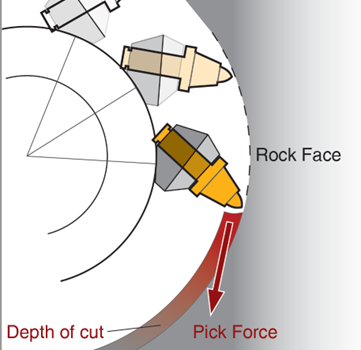

By design, Rockwheel's super power is its powerful cutting along with low noise and low vibration. All of the picks connect with the cutting surface at around a 45o angle, pressing into the rock and chipping off what they connect with. This means little to no over-breakage because the surface isn't being directly pounded like a hammer. With no over-breakage the adjacent structure, rock, etc remain intact and unaffected.

Read more about excavation with adjacent structures on our blog here.

Along with low vibration, Rockwheel's also produce low noise. As such utility contractors employ Rockwheels in urban settings with noise restrictions. The low noise output allows night time work and faster project completion.

Low Vibration output allows Rockwheels to be utilized in foundation and demolition work, especially adjacent to exisiting structures. Trimming secant walls is a very common application because a Rockwheel gives operators a high resolution of control over what's being removed, where it's being removed, and leaving the remaining secant wall intact and sound.